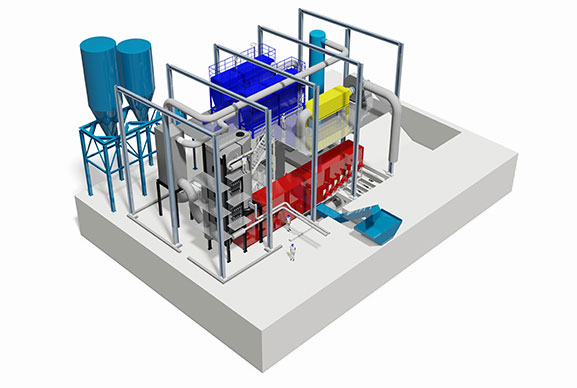

Sewage Sludge Treatment

Thermal sludge treatment

Since 2006 Michaelis has been sucessfully using its patented moved bed system.

This system can treat a wide variety of fuels such as municipal waste, hazardous waste, biomass, refuse-derived fuel, plastics and also sludges.

The Michaelis moved bed system has decisive advantages over the fluidized bed process.

Feature

Michaelis moved bed system

Material and heat transfer

Intensive mechanical mixing

Fuel preparation

Low pre-treatment costs, no uniform grain size necessary

Co-combustion of other fuels

Possible, e.g. refuse-derived fuel, biomass, plastics etc., also liquid and pasty

Dust emissions after firing

Low

Direct desulfurization

Possible

Phosphorus recovery, smelting

Pure ashes are obtained for phosphorus recovery or smelting

Variable capacity

Variable adjustment of the firing capacity possible, combustion of sewage slduge with different calorific values possible

Wear and tear

Low

NOx Emission

Low

Height

Low

Maintenance requirement

Low

Own Consumption

Low

Partial load behaviour

Good

Special Features

• Co-combustion of other fuels possible

• Pure ash for phosphorus recovery or smelting

• Low-height and modular construction

Reference: Incineration plant for municipal and industrial sewage sludge with a thermal oil boiler and flue gas cleaning according to EC standards

Ordinance on the recycling of sewage sludge, sewage sludge mixture and sewage sludge compost (Klärschlammverordnung - AbfKlärV)