SINGLE REACTOR SYSTEM

Innovative Utilization of Sewage Sludge

Michaelis excels in the innovative utilization of sewage sludge, transforming waste into valuable resources through advanced thermal treatment processes. Our state-of-the-art

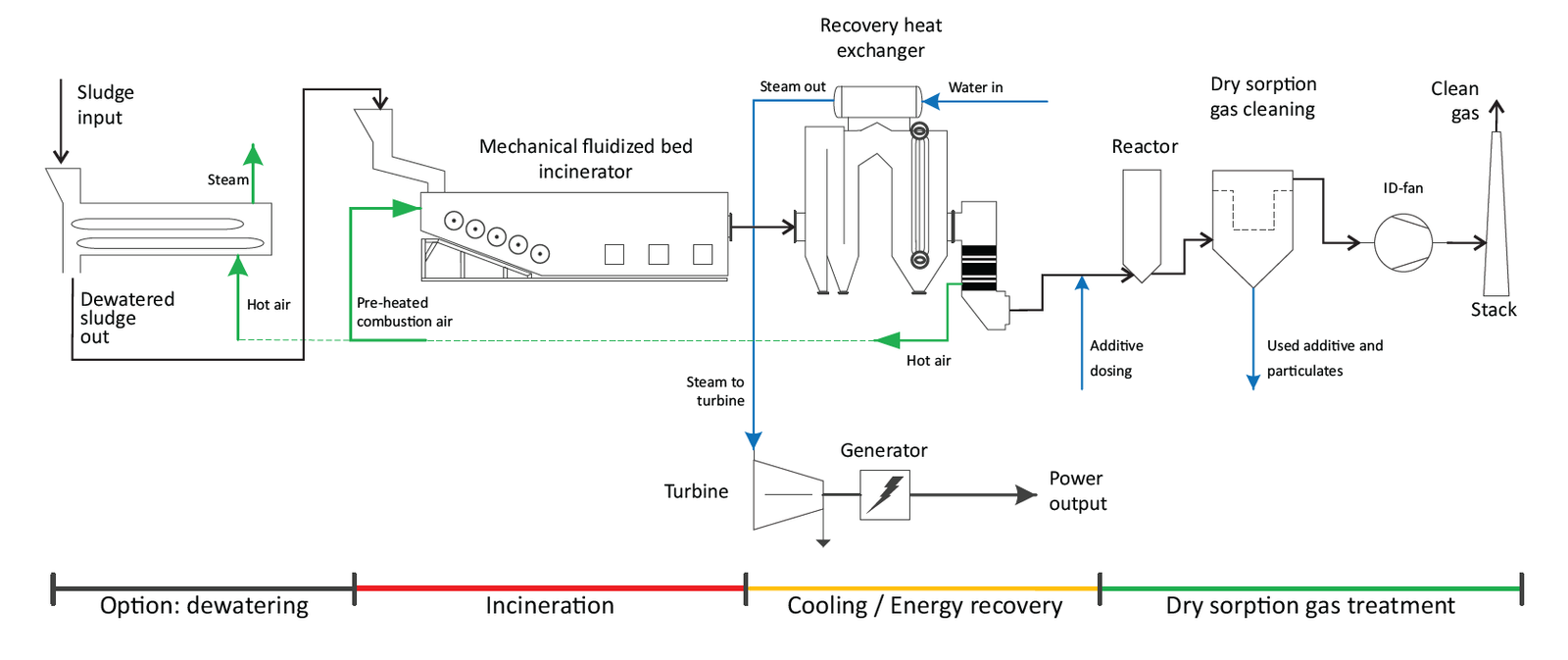

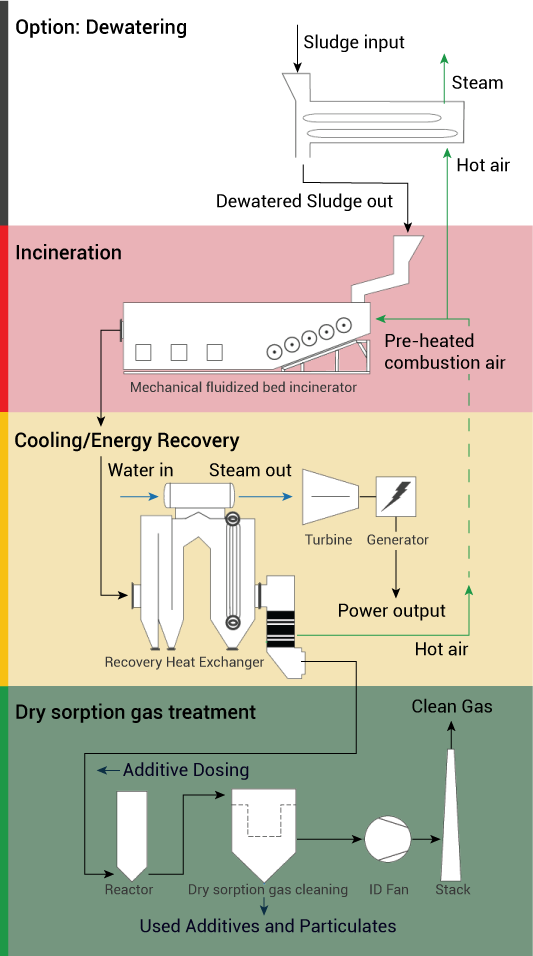

Process of Thermal Treatment

Key Features

Thermal Sewage Sludge Treatment: Efficient thermal processes convert sewage sludge into energy and recover valuable materials.Co-Combustion Capability: The system allows for the co-combustion of other fuels, enhancing flexibility and efficiency.Pure Ash Production: The process yields pure ash, which can be used for phosphorus recovery or metallurgical applications.Low and Modular Design: Our plants feature a compact, modular design, allowing for easy scalability and integration into existing facilities.

Clean Thermal Systems

Solid Waste to Energy Systems

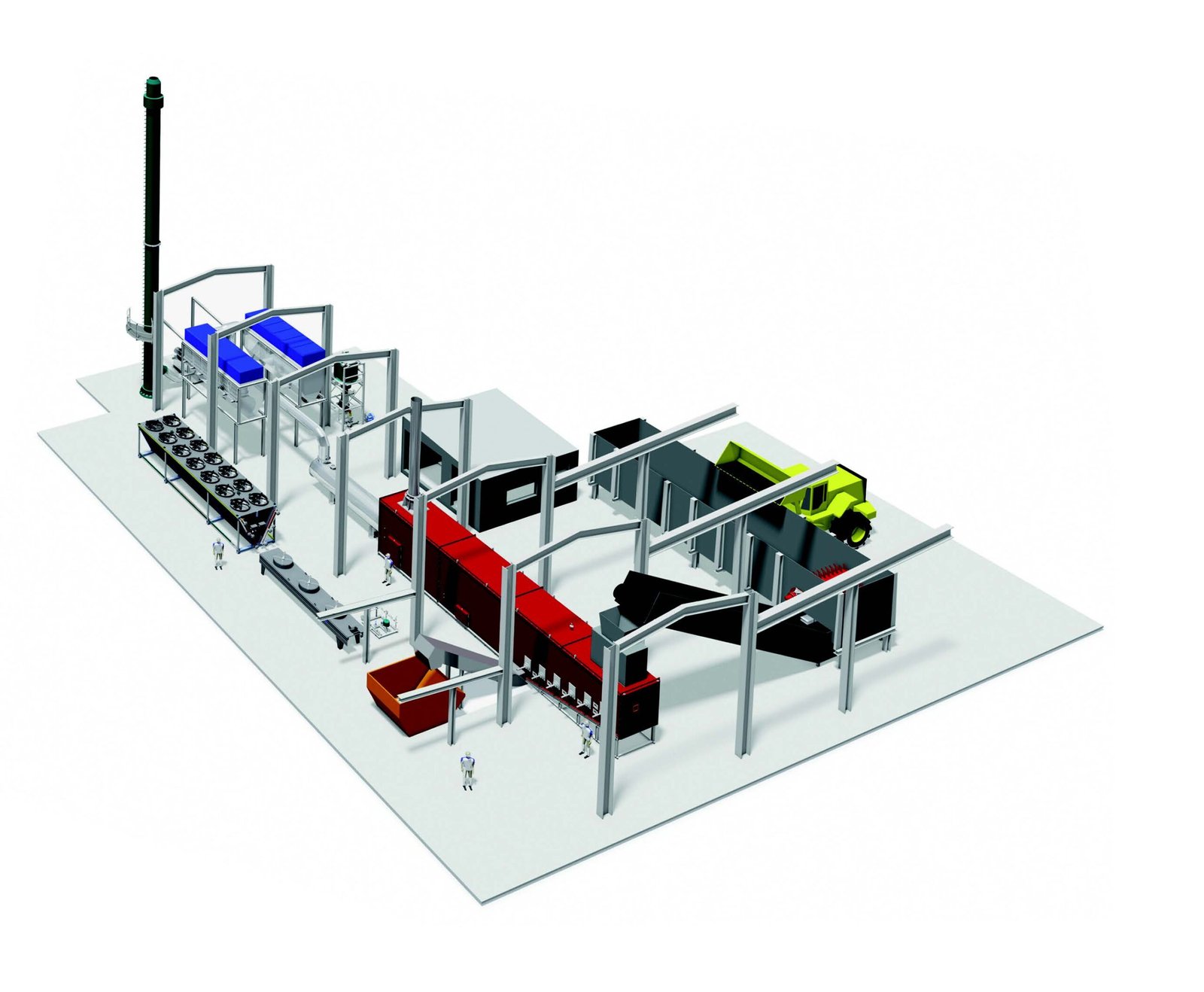

Compact and modular waste management plant for

solid and liquid municipal and industrial wastes.

Integrated recycling and sorting station. Heat recovery

system in combination with seawater desalination / fresh

water preparation / cooling energy / ice production.

Waste Management Systems for Communities and Islands

Industrial waste and sludge incineration plant in Germany.

Emission Control

At Michaelis, we are specialists in emission control, ensuring that our sewage sludge treatment plants consistently meet the highest environmental standards. Our comprehensive emission control systems include:

Dry and Wet Emission Control: Both dry and wet methods are employed to manage emissions effectively.Thermal and Catalytic Processes: Advanced thermal and catalytic processes are used to minimize emissions.Pure Ash Production: The process yields pure ash, which can be used for phosphorus recovery or metallurgical applications.Compliance with EC Standards: Continuous emission measurement ensures compliance with European Commission (EC) standards.

Environmental and Economic Benefits

Energy Recovery: Converts sewage sludge into usable energy, reducing reliance on traditional energy sources.Resource Recovery: Enables the extraction of valuable materials, such as phosphorus, from the ash by-products.Sustainable Solution: Reduces the environmental impact of sewage sludge disposal by minimizing landfill use and promoting resource recycling.Cost-Effective: The modular design and efficient processes result in low operational and maintenance costs.Innovative Technology: Leveraging our patented Paddelofen system for superior performance in sewage sludge treatment.Environmental Compliance: Meeting and exceeding global environmental standards to ensure sustainable operations.Flexible and Efficient: The ability to co-combust other fuels and produce pure ash for various applications.Comprehensive Support: Providing full service and certification to ensure smooth and efficient plant operations.

Get in contact with us

Reach out to learn more about our tire pyrolysis solutions and how we can assist with your specific needs.